Forming Acrylic Sheet Oven

Solid surface ovens and vacuum formers pvc film and structural plastics formers and high pressure laminate formers postformers.

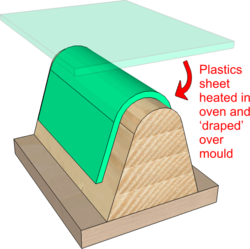

Forming acrylic sheet oven. A mold any object shape you can press the acrylic into to give it shape mallet and or a peen for shaping caution i ve only tried this in an electric oven. Thermoforming acrylic and pvc sheet in eplastics large oven. Note that the minimum radius of the bend you create is 180 times the thickness of the plexiglass sheet. This article uses a sheet about 1 4 thick so all times are about 10 to 15 minutes per step.

The only major variable that can affect the forming process is the thickness of the plastic sheet. We manufacture high qualitythermoforming equipment. Force the plexiglass into the desired shape. For thicker sheets it will take longer and for thinner sheets it will take less time.

It is sheet temperature that dictates the process the end result being not just a better product but also decreased cycle time less scrap less floor space and reduced energy and labor costs. Twenty four hours at 176 f 80 c dries most sheets. Javascript is disabled on your browser. Acrylic oven baking sheet aluminum foil timer felt for handling the acrylic and to prevent scratches tools for forming tools for forming may include.

Acrylic sheets in heating ovens. I can t recommend for. Plexiglass or acrylic sheet this system works well for small pieces of plexiglass in thicknesses of up to 1 8 inch. This device can reduce appreciably the labor required for clamping and unclamping sheets preparatory to forming.

To view this site you must enable javascript or upgrade to a javascript capable browser. Licensed to youtube by wmg merlin redeye distribution on behalf of the leaf label. It is important to provide sufficient clamping of the sheet during the forming process. It can also shorten the time required to transport the heated sheet from the oven to the forming equipment thus minimizing the possibility of cold forming.

To reduce the length of the forming cycle pre dry the sheet in a spare oven and transfer it directly into the forming oven at 176 f 80 c after the drying period. Sheet temperature is one of the most critical elements of the thermoforming process. Modify the timing as necessary. Attempting to create a smaller radius would snap the sheet.